Zirconium nitride (ZrN) is an inorganic compound used in a variety of ways due to its properties.

| |

| Names | |

|---|---|

| IUPAC name

Zirconium nitride

| |

| Other names

Zirconium(III) nitride, Nitridozirconium

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChEBI | |

| ChemSpider | |

| ECHA InfoCard | 100.042.864 |

| EC Number |

|

PubChem CID

|

|

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| ZrN[1] | |

| Appearance | Yellow-brown crystals |

| Odor | Odorless |

| Density | 7.09 g/cm3 (24 °C)[1] |

| Melting point | 2,952 °C (5,346 °F; 3,225 K) at 760 mmHg[1] |

| Insoluble | |

| Solubility | Soluble in concentrated HF, acids[1] |

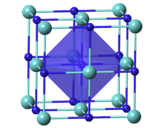

| Structure | |

| Cubic, cF8[2] | |

| Fm3m, No. 225[2] | |

a = 4.5675 Å[2] α = 90°, β = 90°, γ = 90°

| |

| Octahedral[2] | |

| Thermochemistry | |

Heat capacity (C)

|

40.442 J/mol·K[3] |

Std molar

entropy (S⦵298) |

38.83 J/mol·K[3] |

Std enthalpy of

formation (ΔfH⦵298) |

−365.26 kJ/mol[3] |

| Related compounds | |

Related refractory ceramic materials

|

Tantalum carbide Niobium carbide Zirconium carbide |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Properties

editZrN grown by physical vapor deposition (PVD) is a light gold color similar to elemental gold. ZrN has a room-temperature electrical resistivity of 12.0 μΩ·cm, a temperature coefficient of resistivity of 5.6·10−8 Ω·cm/K, a superconducting transition temperature of 10.4 K, and a relaxed lattice parameter of 0.4575 nm. The hardness of single-crystal ZrN is 22.7±1.7 GPa and elastic modulus is 450 GPa.[4]

Uses

editZirconium nitride is a hard ceramic material similar to titanium nitride and is a cement-like refractory material. Thus it is used in cermets and laboratory crucibles. When applied using the physical vapor deposition coating process it is commonly used for coating medical devices,[5] industrial parts (notably drill bits), automotive and aerospace components and other parts subject to high wear and corrosive environments.

Zirconium nitride was suggested as a hydrogen peroxide fuel tank liner for rockets and aircraft.[6]

References

edit- ^ a b c d Lide, David R., ed. (2009). CRC Handbook of Chemistry and Physics (90th ed.). Boca Raton, Florida: CRC Press. ISBN 978-1-4200-9084-0.

- ^ a b c d Sirajuddeen, M. Md. Sheik.; Banu, I. B. S. (2014). "FP-LAPW investigation of electronic, magnetic, elastic and thermal properties of Fe-doped zirconium nitride". AIP Advances. 4 (5): 057121. Bibcode:2014AIPA....4e7121S. doi:10.1063/1.4879798.

- ^ a b c Zirconium nitride in Linstrom, Peter J.; Mallard, William G. (eds.); NIST Chemistry WebBook, NIST Standard Reference Database Number 69, National Institute of Standards and Technology, Gaithersburg (MD) (retrieved 2014-06-30)

- ^ Mei, A. B.; Howe, B. M.; Zhang, C.; Sardela, M.; Eckstein, J. N.; Hultman, L.; Rockett, A.; Petrov, I.; Greene, J. E. (2013). "Physical properties of epitaxial ZrN/MgO(001) layers grown by reactive magnetron sputtering". Journal of Vacuum Science & Technology A: Vacuum, Surfaces, and Films. 31 (6): 061516. Bibcode:2013JVSTA..31f1516M. doi:10.1116/1.4825349.

- ^ Slate, A. J.; Wickens, D. J.; El Mohtadi, M.; Dempsey-Hibbert, N.; West, G.; Banks, C. E.; Whitehead, K. A. (2018). "Slate, A.J., Wickens, D.J., El Mohtadi, M. et al. Antimicrobial activity of Ti-ZrN/Ag coatings for use in biomaterial applications. Sci Rep 8, 1497 (2018)". Scientific Reports. 8 (1): 1497. doi:10.1038/s41598-018-20013-z. PMC 5784091. PMID 29367635.

- ^ US 7736751, Yousefiani, Ali, "Coating for components requiring hydrogen peroxide compatibility", published 2010-06-15, assigned to Boeing Co.